Backflow Preventer — What Is It and How Does It Work?

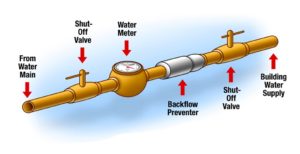

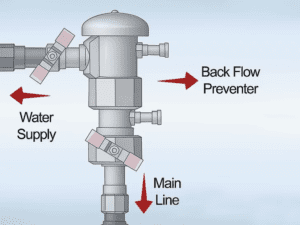

‘Backflow’ is the flow of water in the opposite direction — back into the water supply.

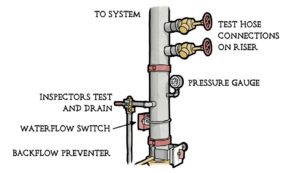

Backflow preventers hold the pressurized fire sprinkler water line from flowing back into the municipal water line — a probable case if there is a loss of pressure from the municipal water line.

Backflow preventers reduce the chances of polluting the municipal water system through cross-contamination.

So, What Actually Is A Backflow Preventer?

So, What Actually Is A Backflow Preventer?

A backflow preventer is a mechanism devised to keep water inside a fire protection sprinkler system and other water-based arrangements installed on a property — securing that it solely travels in one direction: from the water main into the pipes of the system.

Approved backflow assemblies have met the requirements of different certified testing agencies and each one is intended for particular applications. The most common assemblies include:

Double Check Valves (DCV)

Specifically outlined to prevent backflow in fire sprinkler systems, DCVs incorporate an inlet (upstream) shutoff valve, two independently operating spring-loaded check valves (usually inside a single valve body), four test cocks, and an outlet (downstream) shutoff valve.

Reduced Pressure Zones (RPZ)

RPZ backflow preventer assembly is most commonly used when hazardous chemicals like antifreeze or corrosion inhibitors are introduced.

RPZs dilate upon the double check valve notion. With a hydraulically operated relief valve that makes them exceptionally dependable, RPZs integrate an inlet shutoff valve, two spring-loaded check valves separated by a pressure differential relief valve, four test cocks, and an outlet shutoff valve.

Reduced Pressure Principle Detector Assembly (RPDA)

Primarily used in fire sprinkler systems, RPDA is a specially designed assembly composed of a line-size approved reduced pressure principle with a specific bypass consisting of a particular water meter.

How Does A Backflow Preventer Work?

Under normal conditions, the pressure between the two check valves — is sustained at a lower pressure than the supply pressure. If either check valve shall leak — the relief valve is devised to open and discharge water to the outside, ensuring backflow never eventuates.

Please note that RPZ assemblies, while being reliable, encounter much higher pressure and volume loss than double-check assemblies.

Now, inconsistent flow inline pressure (upstream or downstream) will prompt a properly functioning RPZ to periodically release small amounts of water. But during a backflow condition, a large volume of water will flow from the relief valve. And hence, for this reason, RPZ assemblies should not be installed in areas that are subjected to water damage.

Also, it must be noted that both types of backflow preventers scale down the available downstream water pressure.

A proficient contractor must account for this when designing fire sprinkler systems.

Is It Necessary To Have Backflow Preventers In Fire Sprinkler Systems?

Yes. Fire sprinkler systems must have backflow preventers. Municipalities, water purveyors, and plumbing inspectors have outlined, enforced, and set forth plumbing codes and directives for installing backflow preventers so as to protect local drinking supplies. So, please do check and acquire knowledge from your local water authority about the particular requirements for backflow preventers in your area.

Remember: Backflow from fire protection systems can contaminate the potable water. Thus, it is absolutely essential to install backflow preventers in your sprinkler systems. By doing so, you can prevent avoidable accidents — and meet code requirements in the area.

So, ensure to check with your local authority having jurisdiction (AHJ) on the exact backflow prevention requirements in your area, system, and occupancy type.

Let’s Wrap Up:

Thus, if you need to get a backflow preventer installed in your fire sprinkler system or want to get it checked and maintained, be sure to contact www.millbrookfireprotection.com. We can remove or install and double-check and reduce pressure zone backflow prevention assemblies.