What are In-Rack Fire Sprinkler Systems and How Do They Work?

A warehouse fire is the last thing an entrepreneur would ever want.

Nonetheless, they occur every year.

According to the National Fire Protection Association (NFPA):

- Fire departments in the United States respond to an estimated average of 1,210 warehouse fires per year.

- These fires cause an average of $155 million of property damage per year — as well as the death or injury of 22 individuals.

- Electrical or arson fires are the most common causes of such accidents.

Warehouse fires can spread quite rapidly. These flames inflict significant damage to several pieces of equipment and inventory.

The fire can also injure or kill your employees.

Warehouses that store toxic or combustible liquids or chemicals are specifically vulnerable to fires.

Thus, it is critical to take precautionary steps — which is why an in-rack sprinkler is an excellent investment in preventing future loss.

So, what are In-Rack Fire Sprinkler Systems, and how do they Work?

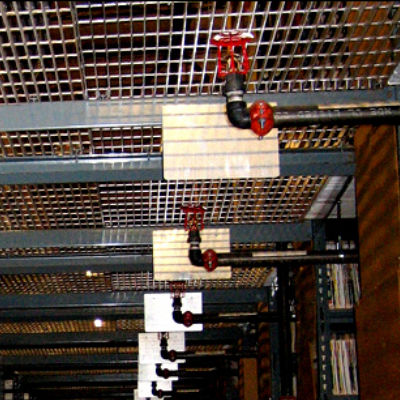

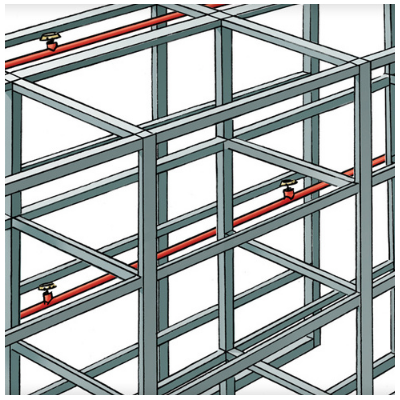

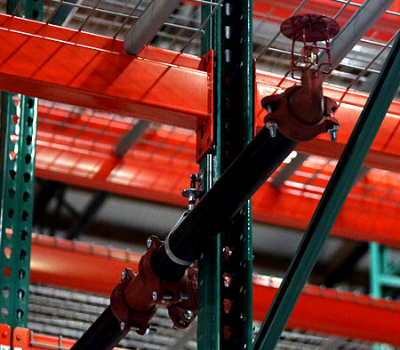

In-Rack Sprinklers are fire suppression systems that are installed throughout a racking structure via a network of pipework.

In-rack sprinklers detect the heat of the fire and restrain and extinguish flames within the racks.

Now, in comparison to overhead sprinklers in your warehouse, in-rack sprinkler systems allow closer proximity to equipment and goods.

Their ultimate goal is to reduce the degree of fire damage to the stocked material.

Why are they installed in Warehouses?

In-rack sprinkler systems are particularly designed to protect racked storage facilities. These installations continuously monitor for smoke and release water into a specific area to minimize damage and downtime.

In-rack sprinkler systems cannot, however, prevent fires. But they certainly can confine the flames to a particular region and extinguish the same in a short period of time.

In-rack sprinkler systems cannot, however, prevent fires. But they certainly can confine the flames to a particular region and extinguish the same in a short period of time.

For adequate protection across the storage space — these sprinklers are arranged along with a network of pipes (within the rack system).

These fire suppression systems are commonly installed in rack structures that are automated and use mechanized picking equipment (controlled by a computer) for loading and unloading the stock.

In-rack fire sprinkler systems are mostly installed in:

• Warehouses

• Automotive Industry

• Retail

• Freezers

• Parking Structures

• Hotels

• Special Hazardous Zones

Advantages of In-Rack Sprinkler Systems

• Proximity to equipment results in quick-fire suppression

• Fires are contained to a specific area and flames are extinguished — swiftly.

• Smoke and heat detection are monitored, continuously.

• Reduces downtime and minimizes inventory damage (of facilities, equipment, and goods).

• These systems are ideal for large industrial shelving and racking systems.

• Installation costs are quite economical, as compared to traditional ESFR sprinkler systems.

• Efficient use of an extinguishing agent (as the fire suppressant is discharged solely in one or a specific number of racks at a particular moment) — resulting in reduced overall cost.

What are you waiting for?

The Millbrook team will come to your warehouse and assist you in determining and designing the most appropriate in-rack fire sprinkler system.

Our experts can guide you in installing a fire protection system that meets your warehouse safety requirements.

To speak with a qualified professional about the best fire safety system for your warehouse, contact us today.

Call on (631) 254-1315 or submit your query on https://millbrookfireprotection.com/contact-us/ — today.